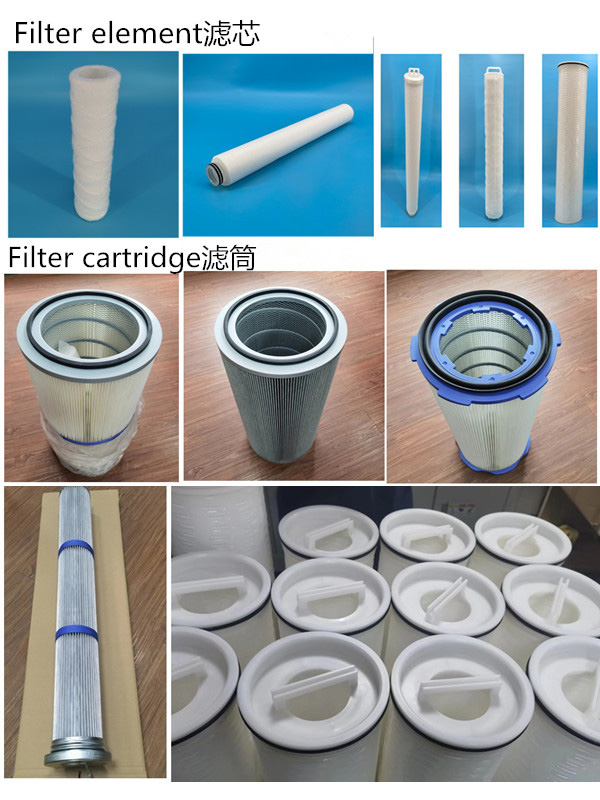

Filter cartridge - The filter cartridge is a commonly used dust collecting device, with the characteristics of high collection rate, low resistance, and easy to put into the flue for sampling. . According to the material, it can be divided into glass fiber filter cartridge and corundum filter cartridge. The most widely used daily is the glass fiber filter cartridge. The glass fiber filter cartridge is composed of ultra-fine glass fibers, and the collection rate of dust particles above 0.5um can reach more than 99.9%.

Product advantages:

1. Greatly increase the effective filter area;

2. Ensure a low and stable pressure difference and increase the airflow;

3. The filter element is small and easy to install;

4. It is especially suitable for industries with high dust concentration.

Scope of application:

Lithium batteries for new energy vehicles (Ningde era), plasma cutting machines for hull workshops in the shipbuilding industry, blast furnace blasting for steel, raw material air compressors for oxygen production stations, gas turbines of various capacities, diesel engines that need to run for a long time, The powder recovery system of central air conditioning system, central control room and other large units with high dust requirements and dust coating.

It is widely used in the consumables in the dust filter of automobile and ship processing.

It is used in filtration and dust removal in the new energy manufacturing industry,

such as the filter in the production and manufacturing process of lithium batteries.

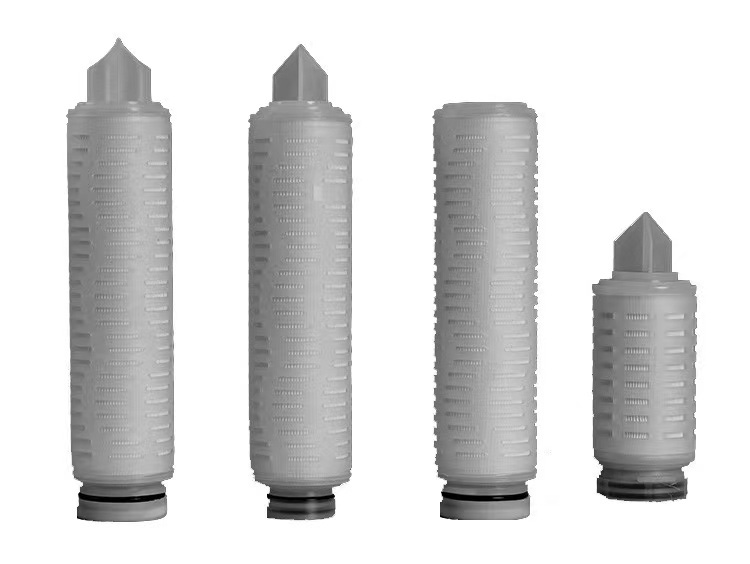

PP pleated filter element

PP pleated filter element is made of ultra-fine polypropylene fiber membrane and non-woven fabric or (silk mesh) inner and outer support layers folded.

The center rod and end cover of the filter element shell are processed by hot-melt welding technology, without any glue, no leakage, and no secondary pollution.

The pleated filter element adopts the folding type, the membrane filtration area is large, the dirt holding capacity is large, the pressure difference is low, and the service life is long. The entire filter element is 100% pure PP material and has a wide range of chemical phase capacity.

Application range:

Electronics industry: reverse osmosis water system pre-filtration, deionized water system pre-filtration.

Pharmaceutical industry: filtration of medicine, biological and plasma products, compressed air and gas filtration.

Food and beverage industry: filtration of mineral water, beverages, fruit juices, and alcohol.

Chemical industry: organic solvents, ink filtration.

Petroleum industry: oilfield water injection filtration.

Others: electroplating liquid, metal cutting liquid, photosensitive resist and magnetic medium filtration, etc.

Other filter products

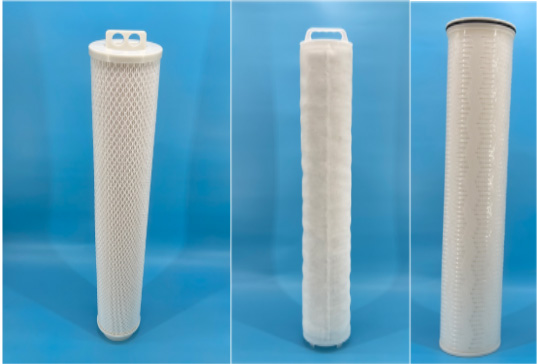

1. Large flow filter element

Our company mainly produces Pall, 3M and Parker high flow filter elements. The large diameter design increases the effective filter area.

Can greatly reduce the number of filter elements and reduce the size of the filter outer wall. In addition, the high-flow filter element has a favorable price and high quality.

1. Large flow means using a smaller number of filter elements, reducing labor and operating costs;

2. Large flow means the use of a smaller size filter housing, which reduces investment costs and saves floor space;

3. The replacement of the filter element is faster, easier and safer;

4. O-ring ensures the reliability of the filter;

5. The hot-melt adhesive polypropylene material can prevent particles from being released and unloaded, which is different from ordinary wire-wound filter elements;

6. The folding surface design makes the pressure drop of the high-flow filter element lower than other filter elements and has a longer service life;

7. Allow high-flow media to pass through the filter material, which has the advantages of high efficiency, low pressure loss and long life;

8. The inside and outside structure of the filter element makes it easy to replace the filter element, while keeping pollutants intercepted inside the filter element;

9. The β value of the filter element reaches 3000.

10. Multiple filter elements can be installed in the filter housing, which can use a wide range of flow, whether it is starting or continuous operation;

11. The filter element is durable, and the filter can be configured in the least and most economical way.

2. PP melt blown filter element

The melt blown filter element is a tubular filter element made of non-toxic and odorless polypropylene particles through heating, melting, spinning, traction, and forming. If the raw material is mainly polypropylene, it can be called PP melt blown filter element. It is not only used in large-scale water purification, but also has outstanding chemical compatibility and is suitable for the filtration of strong acids, strong alkalis and organic solvents. Strong dirt holding capacity, long service life and low cost. In addition, the melt blown filter element has a favorable price and high quality.

1. Filtration efficiency and filtration accuracy, uniform filter element pore density. The filtration efficiency is over 99%.

2. The filter resistance is small, the filter flow is large, the dirt holding capacity is large, and the service life is long. The fiber diameter and gap of this product are adjustable during the production process. The inner layer of the filter element is small and the outer layer is large, which increases the flow and holding capacity. .The filter element is not easy to be blocked. Extended service life.

3. It has high cleanliness, no pollution to water, acid and alkali resistance, organic solvents, and corrosion.

4. High strength, the filter element will not be deformed when the water pressure difference between the inlet and outlet of the filter exceeds 0.4Mpa, and the filtration efficiency will not decrease when the temperature exceeds 90°C.

5. This product has extremely high hydrophilicity after treatment and modification of polypropylene, and can absorb ten times the weight of water, so it can be used for oil-water separation.

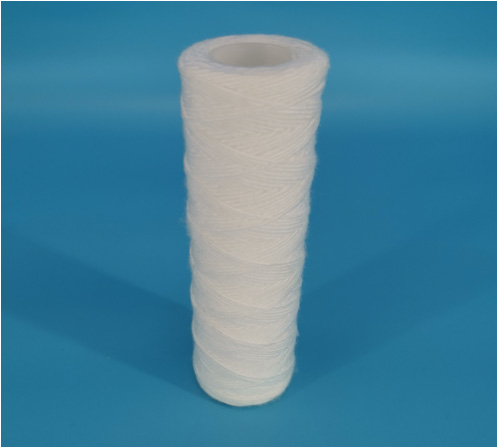

3.PP wire wound filter element

The wire wound filter element is a deep filter element used for low viscosity and low impurity filtration. It is made of textile fiber thread (polypropylene thread, absorbent cotton thread, etc.), which is precisely wound on the porous framework (polypropylene or stainless steel) according to a specific process. ) It is made above, with a dense honeycomb structure outside, which can effectively remove suspended solids, particles, rust and other impurities in the fluid, and has very good filtering characteristics and adsorption. In addition, the wire wound filter element has a favorable price and quality Superb.

1. High filtration accuracy, small pressure difference, large flow, large dirt holding capacity and long service life.

2. The filter pore size is small inside and large outside, with good deep filtering effect.

3. The filter element is made of different materials to ensure various liquid filtration requirements and achieve the ideal filtration effect.

Factory photos:

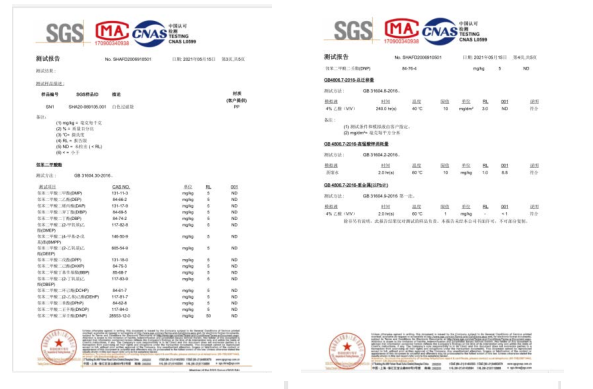

Product SGS certification

Product summary

电话:+860512-57886027

电话:+860512-57886027 邮箱:

邮箱: 地址: Room 1902, XinDuYinZuo, No. 177, Changjiang Middle Road, Kunshan, Jiangsu

地址: Room 1902, XinDuYinZuo, No. 177, Changjiang Middle Road, Kunshan, Jiangsu